Preparation of Nd:YLF Raw Materials by Melting Method and Study on Their Crystal Growth and Properties - 03

2 Results and Discussion

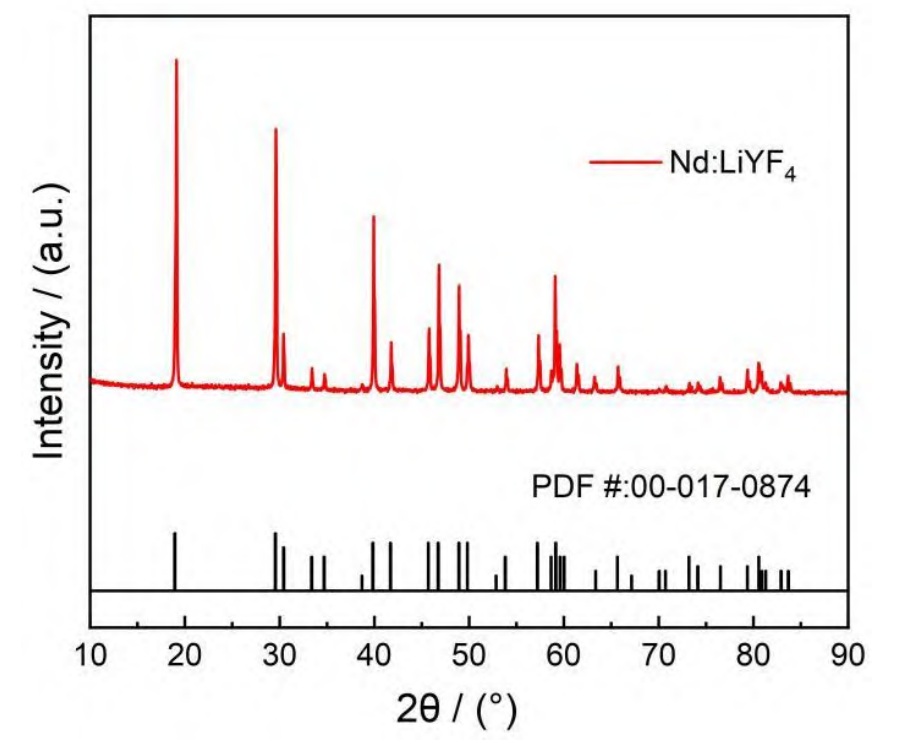

Figure 4 is the XRD spectrum of the polycrystalline material prepared by the melting method. Its diffraction peak position and relative intensity are basically consistent with the YLF standard card (PDF#00-017-0874), and the agreement is good, indicating that the polycrystalline material is pure YLF phase, without impurities such as fluorine oxides, YF3, and LiF, and the incorporation of N3+ has no effect on the structure of the matrix crystal. Therefore, the polycrystalline Nd:YLF (www.wisoptic.com) raw material prepared by the melting method has high crystal phase purity, which improves the ability of the raw material to resist oxidation and deliquescence, and is an ideal raw material for high-quality crystal growth. Analysis shows that the nearly closed melting device structure used in this study can obtain a temperature field with a highly uniform temperature distribution. At the same time, melting the raw material at a temperature slightly higher than the melting point of Nd:YLF can achieve full reaction of the raw material and obtain pure phase Nd:YLF; at the same time, by fully salvaging the fluorine oxide floating on the surface of the melt, the high purity of the Nd:YLF polycrystalline raw material is further guaranteed.

Fig. 4 XRD pattern of polycrystalline materials from the melting method

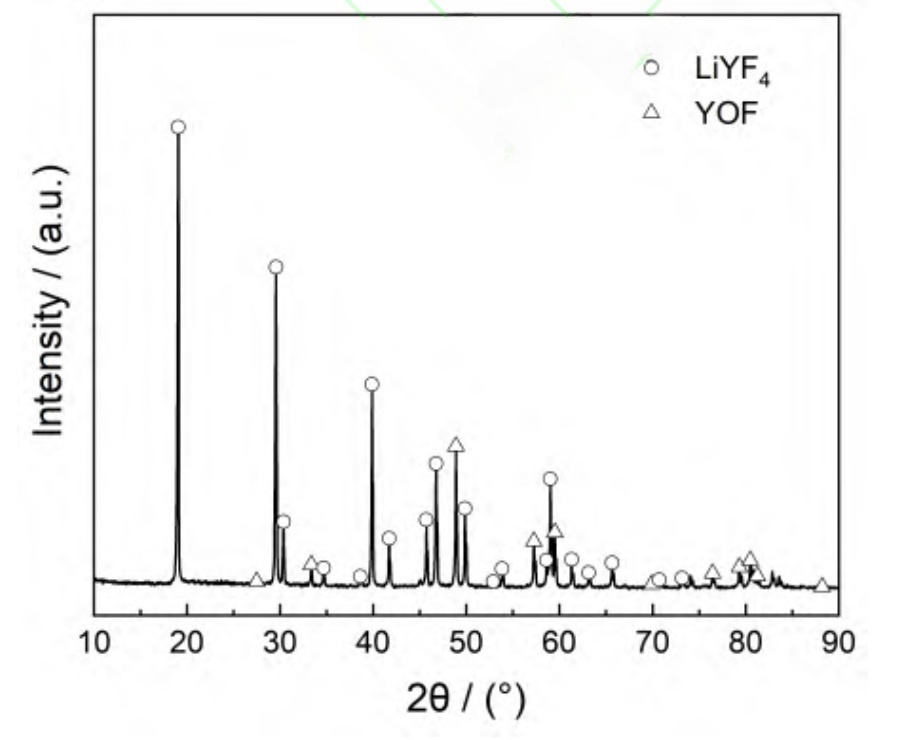

As can be seen from Figure 3, a layer of white opaque compound is attached to the surface of the crystal grown by the mixed raw material, while there is no such substance on the surface of the crystal grown by the raw material prepared by the melting method. The white substance was tested and analyzed by XRD, and the test results are shown in Figure 5. The XRD spectrum was analyzed by MDI jade software, and it was found that in addition to YLF, its main components also contained a large amount of YOF. This may be caused by the presence of YOF in the initial raw material; it may also be caused by the reaction of YF3 in the initial raw material with the trace amount of H2O released in the growth furnace as the temperature rises in the Ar atmosphere, as shown in Formula (1), and adhered to the surface of the grown crystal during the crystal growth process.

H2O + YF3 → YOF + 2HF ↑ (1)

Fig. 5 XRD pattern of whiteness from crystal grown with mixed component raw materials

The outer surface of the crystal grown by the melting method is attached with a small amount of black substance, which is formed by the carbon volatilized from the graphite crucible.

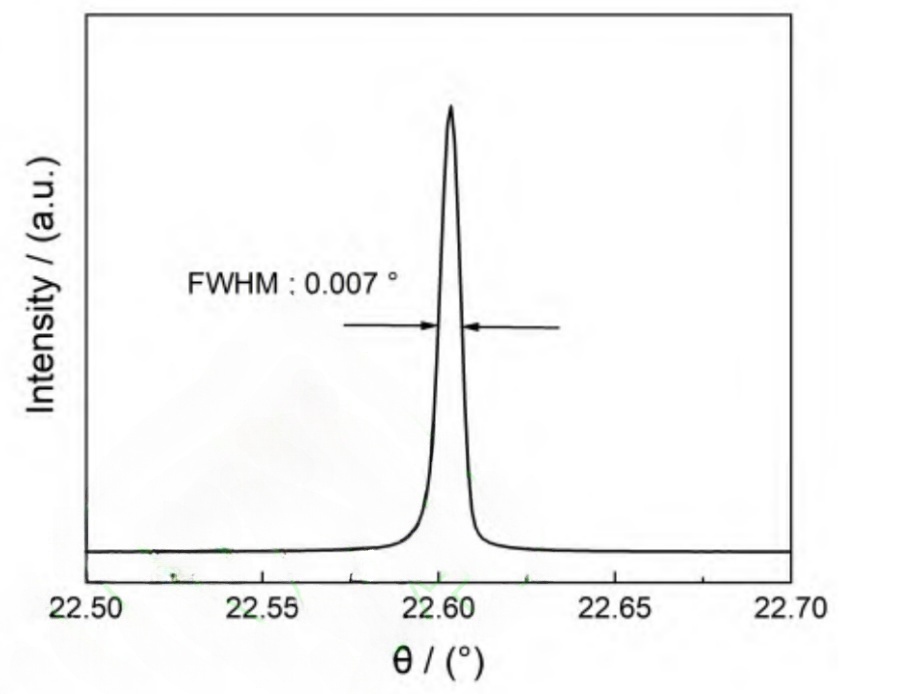

Figure 6 shows the single crystal rocking curve of the sample with (100) crystal orientation. The single crystal rocking curve is a traditional method to characterize the quality of the crystal. The smaller the FWHM, the better the crystal quality and the more uniform the crystal composition and structure. It can be seen that the rocking curve in the figure has only a single diffraction peak, no splitting occurs, is symmetrical, has a sharp peak shape, and a half-height width of 0.007°, indicating that the grown Nd:YLF crystal (www.wisoptic.com) has good crystal quality.

Fig. 6 X-ray rocking curve of Nd:YLF crystal