Preparation of Nd:YLF Raw Materials by Melting Method and Study on Their Crystal Growth and Properties - 02

1 Experiment Method

1.1 Raw material preparation

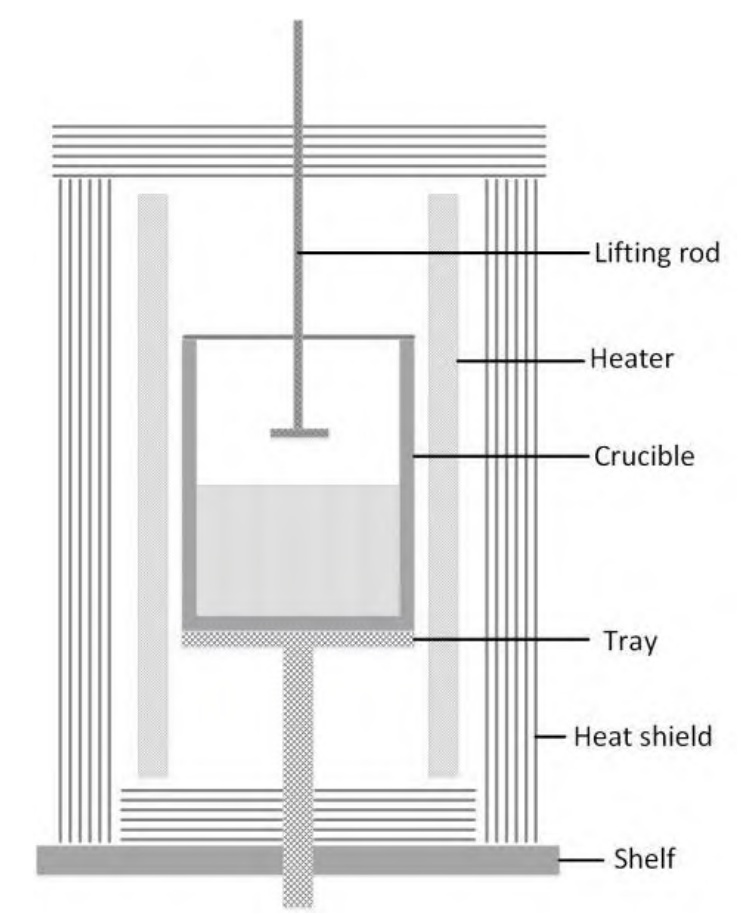

YF3, LiF and NdF3 with a purity of 99.999% were used as initial raw materials. They were accurately weighed in a vacuum glove box at a ratio of n(LiF):n(YF3):n(NdF3)=51:48:2, loaded into a raw material bottle and mixed thoroughly. Then, the raw materials are poured into the high-purity graphite crucible in the melting device shown in Figure 1, and the furnace door is closed in time to draw a vacuum. When the vacuum degree in the furnace is lower than 1×10-3 Pa, the temperature is raised and the vacuum is continued during the heating process. When the temperature is raised to 700 °C, high-purity Ar gas is filled to 1×104 Pa, and then the vacuum is drawn to 1×10-3 Pa. After three cycles, the gas is filled to 1.2×105Pa. The temperature is continued to rise to 820~850 °C and kept constant for 2~10 h. In order to reduce the adhesion of the Nd:YLF melt in the process of lifting the floating objects from the melt surface, the temperature is then raised to 870~900 °C. The salvage rod is lowered. The lower part of the salvage rod is made of platinum. After contacting the melt, it continues to fall 2~3 mm and then pulls upward at a rate of 2.0~5.0 mm/h to gradually lift all the floating objects on the melt surface away from the melt surface. Finally, the temperature was lowered to room temperature at a rate of 100 °C/h. The crystallized polycrystalline raw material was taken out as shown in Figure 2.

Fig. 1 Schematic diagram of the raw materials melting device

Fig. 2 Polycrystalline material prepared by melting method

1.2 Crystal Growth

The crystal growth was carried out by the resistance heating melt pulling method. The heating element was a graphite heater. The growth atmosphere was high-purity Ar gas, which was circulated for 3 times. Since the YLF crystal needs to grow in a melt rich in LiF, and LiF is volatile at high temperature, a small amount of LiF is added and placed at the bottom of the crucible, and covered by a polycrystalline material prepared by the melting method. After the raw material is melted, the seed crystal is dropped in time for crystal growth, and the seed crystal orientation is (100). The size of the high-purity graphite crucible used is ϕ 100 mm×100 mm, the crystal growth pulling speed is 0.6~1.2 mm/h, the rotation rate is 5~10 r/min, and after the growth is completed, it is cooled to room temperature at a cooling rate of 30~40 °C/h. Finally, a complete Nd:YLF (www.wisoptic.com) crystal with a size of ϕ 35 mm×140 mm is grown, as shown in Figure 3(a). Figure 3(b) shows a crystal grown from a direct mixture of YF3, LiF, and NdF3 raw materials. Comparing the two, it can be seen that growing crystals using molten raw materials can effectively reduce the white opaque material on the crystal surface.

Fig. 3 Nd:YLF crystals grown by Czochralski method

(a) Crystal grown with the polycrystalline material prepared by melting method; (b) Crystal grown with mixed component raw materials

1.3 Testing and Characterization

X-ray powder diffraction analysis (XRD) was performed on the polycrystalline raw materials, white substances on the outer surface of the crystals and the grown crystals prepared by the melting method using a χ’Pert-Pro MPD X-ray diffractometer. The target material was Cu (Kα=0.154056 nm), the scanning range (2θ) was 10°~90°, and the scanning step was 0.033°. The X-ray rocking curve (XRC) of the (100) crystal orientation of the crystals grown by the melting method raw materials was collected. The test range was 22.5°~22.7°, and the scanning step was 0.001°. The element content of the initial shoulder of the crystal was measured by Laser Ablation Inductively Coupled Plasma Mass Spectrometry (LA-ICP-MS). The transmission spectrum of the crystal (sample thickness 0.5 mm) was measured using a Lambda-950 spectrophotometer, and the fluorescence emission spectrum and fluorescence lifetime of the crystal were measured using an Edinburgh FLSP-920 fluorescence spectrometer.