High-Power Mid-Infrared Ultrafast Sources at 2 - 5μm Based on Dual-Wavelength Source - Part 7

3 Difference frequency generation of high-power mid-infrared ultrafast light sources

3.2 Difference frequency generation for producing high-power mid-infrared ultrashort pulses at 3μm

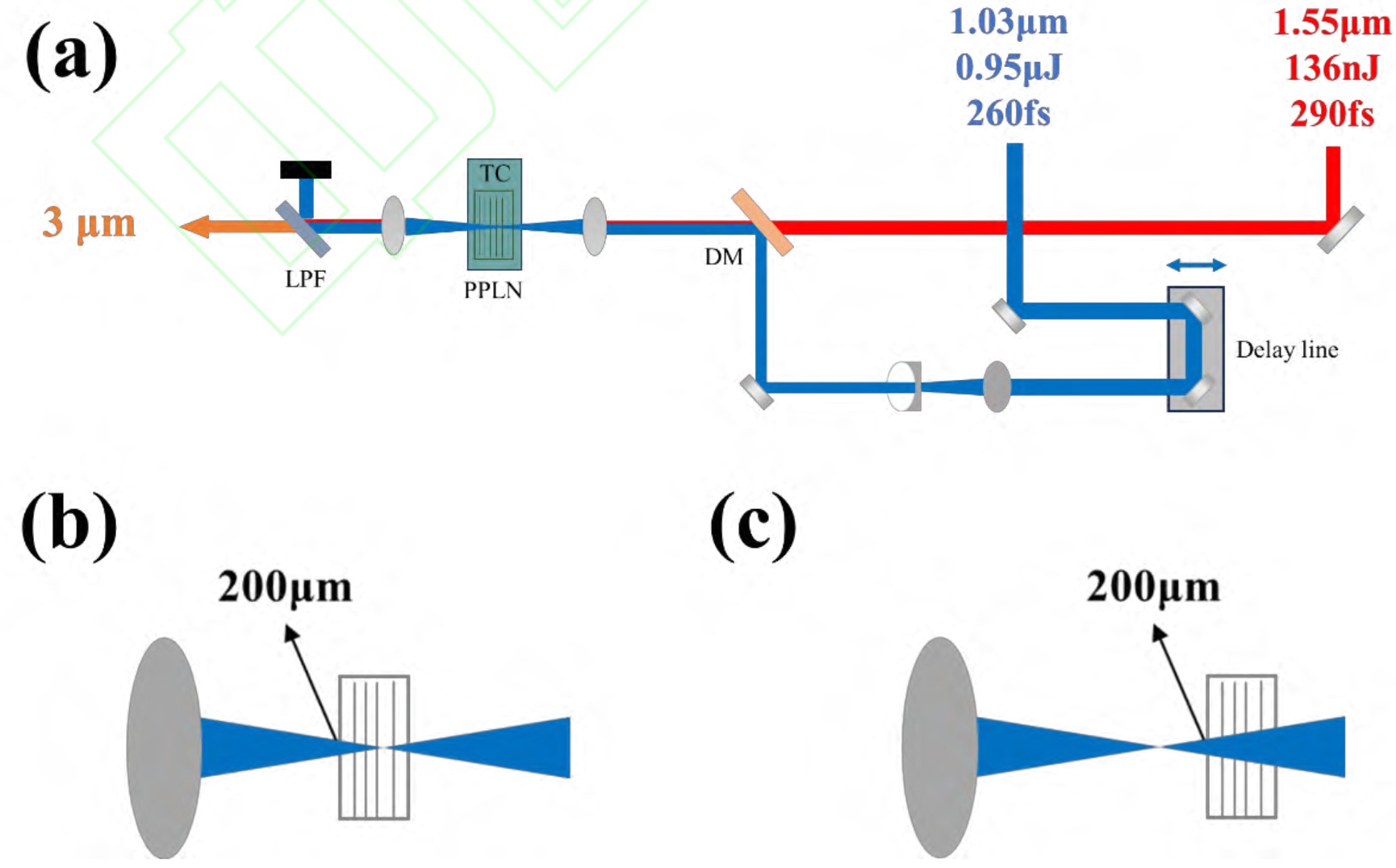

We built a DFG (Difference Frequency Generation) system based on a high-power dual-wavelength ultrafast fiber laser, as shown in Figure 7(a). The pump pulse has a central wavelength of 1.03 μm, an energy of 0.95 μJ, and a pulse width of 260 fs; the signal pulse has a central wavelength of 1.55 μm, an energy of 136 nJ, and a pulse width of 290 fs. After adjusting the temporal delay of the pump pulse relative to the signal pulse using a delay line, the two beams are combined by a short-pass dichroic mirror (DM) and then focused into a PPLN crystal (www.wisoptic.com) using a plano-convex lens with a focal length of 250 mm. The PPLN crystal has a fan-out design with a continuously adjustable polarization period between 21 and 34 μm, and dimensions of 15 × 1 × 3 mm³. Both surfaces of the crystal are coated with antireflection coatings for the wavelength ranges of 1.04–1.09 μm, 1.3–1.7 μm, and 2.7–5.2 μm to prevent Fresnel reflection; a temperature-controlled oven heats the crystal to 80 °C to prevent photorefractive damage. After difference frequency generation of the pump and signal pulses in the 3 mm PPLN crystal, the resulting mid-infrared pulse, along with the idler light, is collimated by the plano-convex lens and then reflected by a long-pass filter (LPF). The transmitted laser beam is the final output of the mid-infrared ultrafast pulse laser.

Fig.7. The DFG-based 3μm high-power mid-infrared laser. (a) Drawings of experimental

installations; (b) When the focal point is behind the front surface of the crystal; (c) When the focal

point is located before the front surface of the crystal

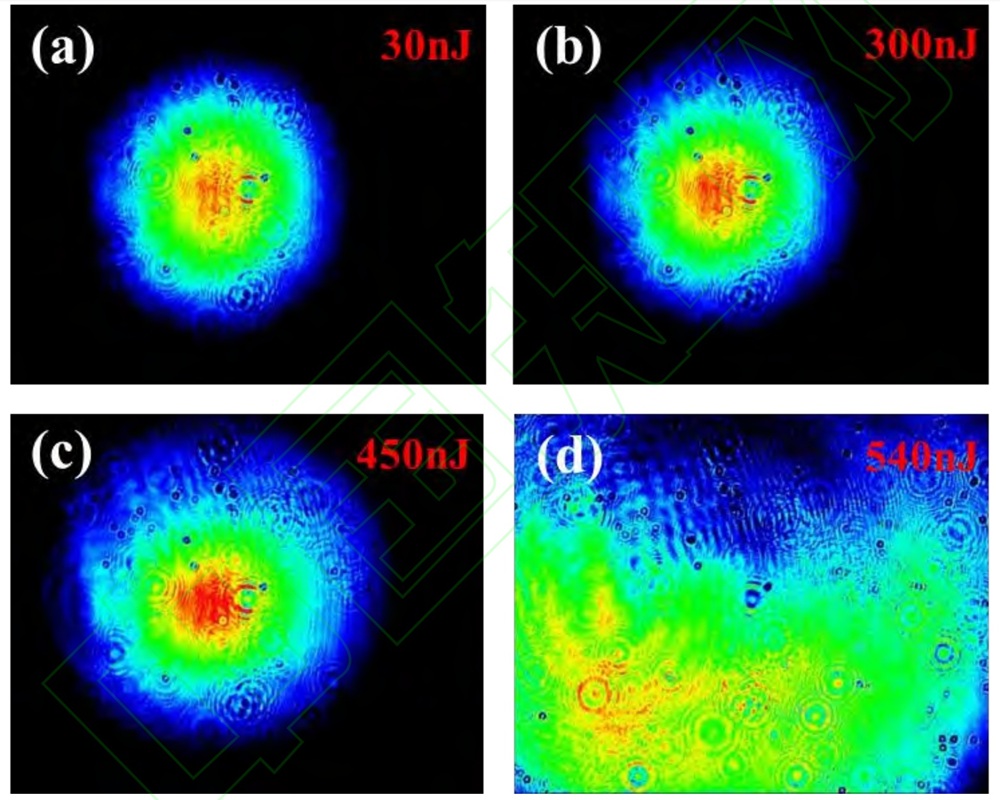

During the DFG process, the size of the laser spot within the crystal directly determines the strength of the nonlinear interaction. To maximize the nonlinear interaction strength without causing damage to the crystal, the laser spot size must be kept above a critical threshold. In the experiment, the laser spot diameter at the front surface of the crystal was initially set to 200 μm. After collimation by a lens at the output end, the spot shape was recorded using a CCD camera. The resulting spot patterns under different pump powers are shown in Figure 8.

Fig.8. Far-field light spot diagram at different pump power.

When the pump pulse energy increased from 30 nJ to 300 nJ, the shape of the beam spot remained essentially unchanged. However, when the pump pulse energy reached 450 nJ, the beam spot shape changed slightly, with noticeable divergence at the outer edge. At 540 nJ, self-focusing occurred, causing a dramatic change in the beam spot shape; further increasing the pump energy would damage the PPLN crystal (www.wisoptic.com). By positioning the crystal at the beam focus and ensuring a 200 μm diameter spot at the crystal's front surface (as shown in Figure 7(c)), and after optimization, self-focusing could be avoided even with a pump energy of 900 nJ and a signal energy of 120 nJ.